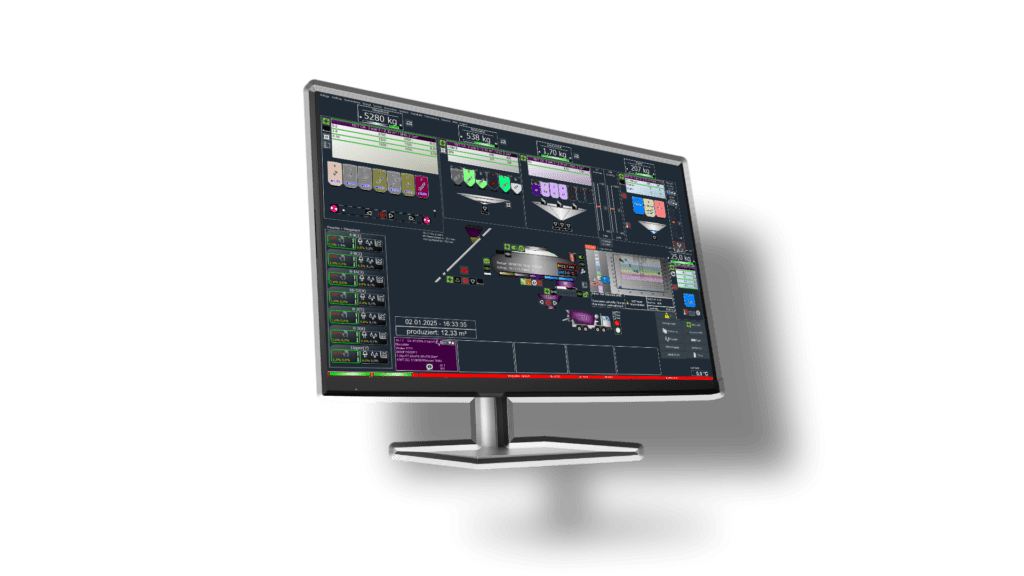

s-mix - Process control ready-mixed concrete

The s–mix process control system for ready-mix concrete can be adapted to different types of concrete and customer requirements. Whether high-strength concrete or special mixtures for special applications – the adaptability of the system is impressive.

The environmental impact can be reduced through precise dosing and the use of recycled materials. The s–mix ready-mix concrete process control system helps to make the use of resources sustainable. The integration of s–mix process control for ready-mix concrete into production represents significant progress in the construction industry. This technology not only optimizes quality requirements, but also provides economic benefits.

Companies that rely on s–mix position themselves as pioneers in providing high-quality, tailor-made concrete for demanding construction projects.

Key functions:

- Intuitive operation

- Process visualization of your complete system

- Operating modes automatic – semi-automatic – manual

- mixing plant control system (calibratable)

- Process optimization

- Simple controls for small and mobile systems

- Complex controls for large systems with multiple mixers

- customer-specific project solutions

- production monitoring

- Program modules – feed control, binding agent injection

- modular retrofitting of all system types

- Consistency measurement and control with s–cons – Consistency control

- Water dosing with s–visco – Water dosing

- Precise humidity, temperature & density measurement

- Energy management

- Networking with other applications from the s–synergy portfolio

- Connection to external “process mining software” e.g. Alcemy

- Machine learning and AI connections